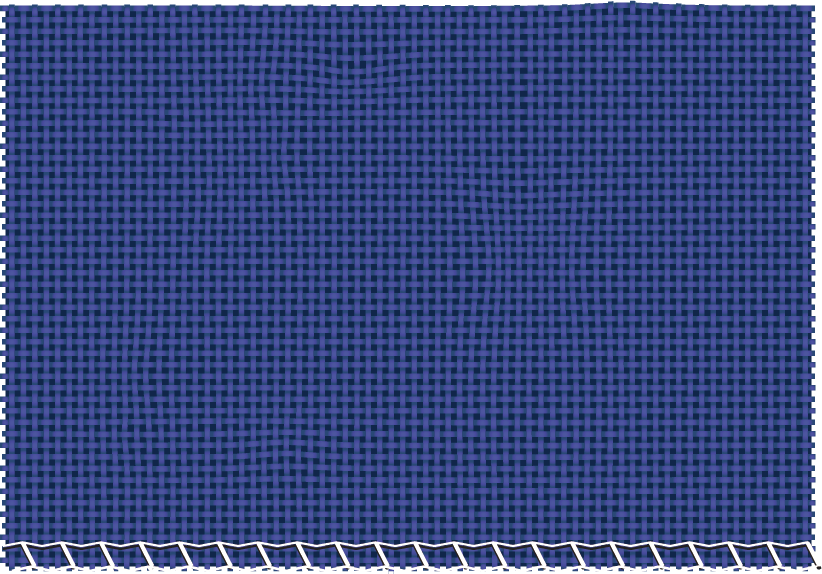

Seam construction determines the suitability of protective coveralls. Various methods exist, including overlocked, tape-sealed stitched, ultrasonic, and bound stitched seams. The commonly mentioned seams for coveralls are the 3 or 4 thread overlocked seams.

Normal 3-thread seam

Stronger 4-thread overlocked seam

In comparison to the commonly used 3-thread overlocked seam, the 4-thread overlocked seam proves to be a simpler yet highly effective method for securing the fabric together and providing protection against both liquid splashes and dry particulates.